Introduction:

EVA film can be used for solar cells, crystalline silicon cells, thin film photovoltaic cells and other components within the packaging material. The content of 30% -33% of the EVA resin as main raw material, made through a special process, with strong bonding, high light transmission, anti-aging characteristics.

Feature:

1) Excellent durability, such as weather resistance, high temperature and high humidity resistance, UV light resistance.

2) Excellent adhesion to glass, metal and plastics PET, TPT maintaining long term adhesion

3) Excellent light and transmittance and transparency.

4) Inactivation and harmless in solar cell during processing.

5) Have a high cross linking rate after lamination.

6) Good encapsulating property.

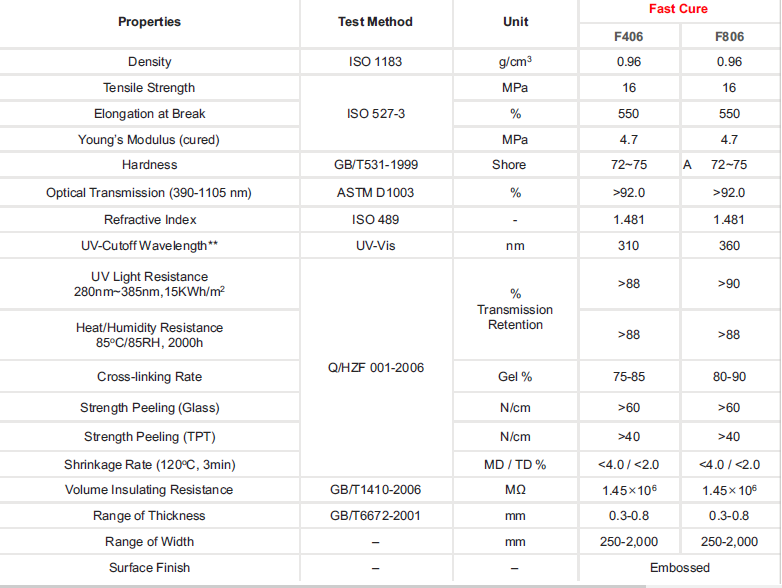

EVA solar film data sheet

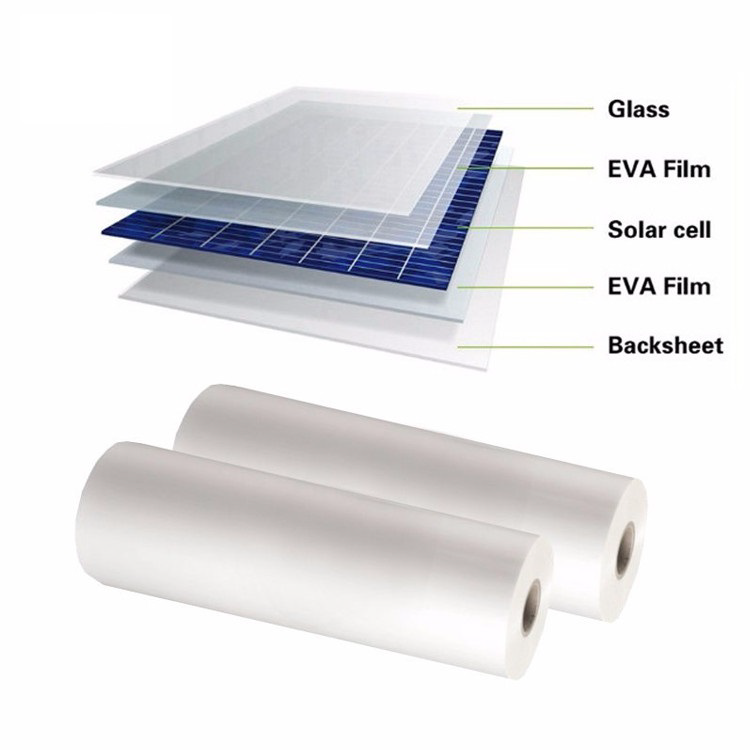

Processing of EVA lamination film to glass

Laminating:

laminate the glass, EVA film, connected silicon cells, EVA film, TPT backsheet foil in sequence.

Vacuum pumping:

Place above laminated pieces into the lower room of the double-vacuum press. Then the upper room and the lower room are vacuumed synchronously about 6min.

Heating:

the upper and the lower room are kept vacuum, meanwhile heat the laminated pieces.

Press:

Laminated pieces are heated under 135°C-140°C conditions, the upper room cancel vacuum and get back to atmospheric pressure. At that time the lower room is still kept vacuum, that is to say, the upper room press on the laminated pieces of the lower room.

Curing:

Isothermal curing under the curing temperature.

Cooling and framing:

After isothermal curing, cancel the vacuum of the lower room, open the top of the press, and take out the laminated modules. Then cut off the extra EVA of composite lamination edge. Moreover seal frame and equip the termainal box, assemble PV modules at last.

Caution during laminating

1, to ensure a constant temperature and humidity in the storage room and use of EVA film,

2, To avoid static electricity generated in the cutting process, the proposed installation in addition to static devices. Staff are required to wear dust-proof clothing and a dust cap, to avoid head EVA film on the hair off to using skim gloves.

3, cut into a sheet of EVA film to be sealed to prevent dust, gloves and other fibers and other foreign matter contamination.

4, In addition to the workshop should be equipped with mosquito device to prevent mosquito pollution diaphragm.

5, In order to facilitate the laying of pumping air bubbles and stick with the cells, place the frosted side facing cells.

6, It is recommended near the paper tube around each roll and do not use the outermost circle.

Product Storage

Products must be stored indoors, the temperature control in the range of 0 °C -30 °C, relative humidity below 60%, away from heat and dust, avoid direct sunlight.

Lossless out of the box should be checked before packing.

Out of the box, the product should be used as soon as possible, is not used up part of the package must be resealed.

Stored no longer than six months from the date of production is best used within three months.

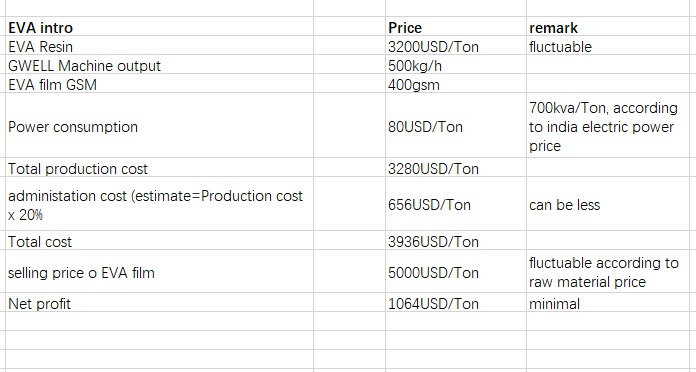

EVA film production Cost analysis

GWELL provide the turnkey solution for EVA film production, welcome to contact us.

Contact: David Dai

Phone: +86 15906228622

E-mail: [email protected]

Whatsapp:+86 15906228622

Add: NO.16 Donglin Industry Park, Taicang,Jiangsu Province, China

We chat