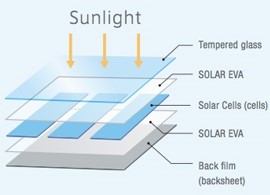

Ethylene Vinyl Acetate (EVA) used in the Photo-Voltaic(PV) industry as an encapsulation material for crystalline silicon solar cells in the manufacture of PV modules. Solar power has been spotlighted as a shining example of clean energy. Photovoltaic encapsulant sheets prevent water and dirt from inltrating solar modules and serve as shock-absorbers that protect the cell.

Solar EVA sheeting is a milky colored rubbery substance that, when heated, becomes a transparent protective film over your solar cells. Solar cells are sensitive to moisture, oxygen and weather. If not protected, they will degrade with time and loose their ability to produce energy. Solar EVA film will protect your solar panels for a long time with little loss in performance. If you can squeeze solar EVA encapsulant film into your budget, it is highly recommended. The professionals recommend using a vacuum and a large oven to properly seal and cure your EVA sheet onto the solar panels. Most of us do not have the ability to do so. Many DIYers have tried, with varying levels of success.

Weather resistance were added for use in severe environments with sunshine.

§ Excellent durability (high temperature, high humidity, and weather resistance)

§ Excellent adhesive bonding to glass, cell, and back side film (backsheet)

§ Excellent encapsulating properties during the lamination process

§ Excellent optical transmission and transparency

§ Excellent flexibility, protecting cells from physical stress during the lamination process

BACKSHEET

Backsheet and/or also called Tedlar protect PV modules from UV, moisture and weather. Solar Array they insulate the electrical load of the modules, which can operate up to 1000 VDC. These functions are essential for the PV modules functionality, longevity and safety of people who work with and near the module.

The solar cell back sheet is the outermost layer of the PV module. The PV back sheet is designed to protect the inner components of the module, specifically the photo-voltaic cells and electrical components from external stresses as well as act as an electric insulator. In order to accomplish this, the solar back sheet must be a robust construction, typically a three layer laminate, and have high dielectric properties. Photo-voltaic back sheets are available in many different constructions to accommodate a wide variety of module types and technologies. We provide every solar back sheet solution under the sun!

Features:

§ Improved module efficiency through optimized reflectance characteristics

§ Excellent stability under damp heat and freeze-thaw conditions

§ Superior bond strength across environmental extremes

§ Superb "tear" bond to EVA

§ Easily cleanable

§ Chemically resistant

GWELL provide the turnkey solution for EVA and backsheet production project, welcome to contact us.

Contact: David Dai

Phone: +86 15906228622

E-mail: [email protected]

Whatsapp:+86 15906228622

Add: NO.16 Donglin Industry Park, Taicang,Jiangsu Province, China

We chat